It all starts with high quality raw materials

To help design the best garments in the textile industry, Emperali Impex offers zero compromise on raw material quality. And that means sublime yarn selection. Let’s not forget that Pakistan is a global leader in possessing the finest yarn selections around the world. And this makes the process easier for garment producing companies like ours.

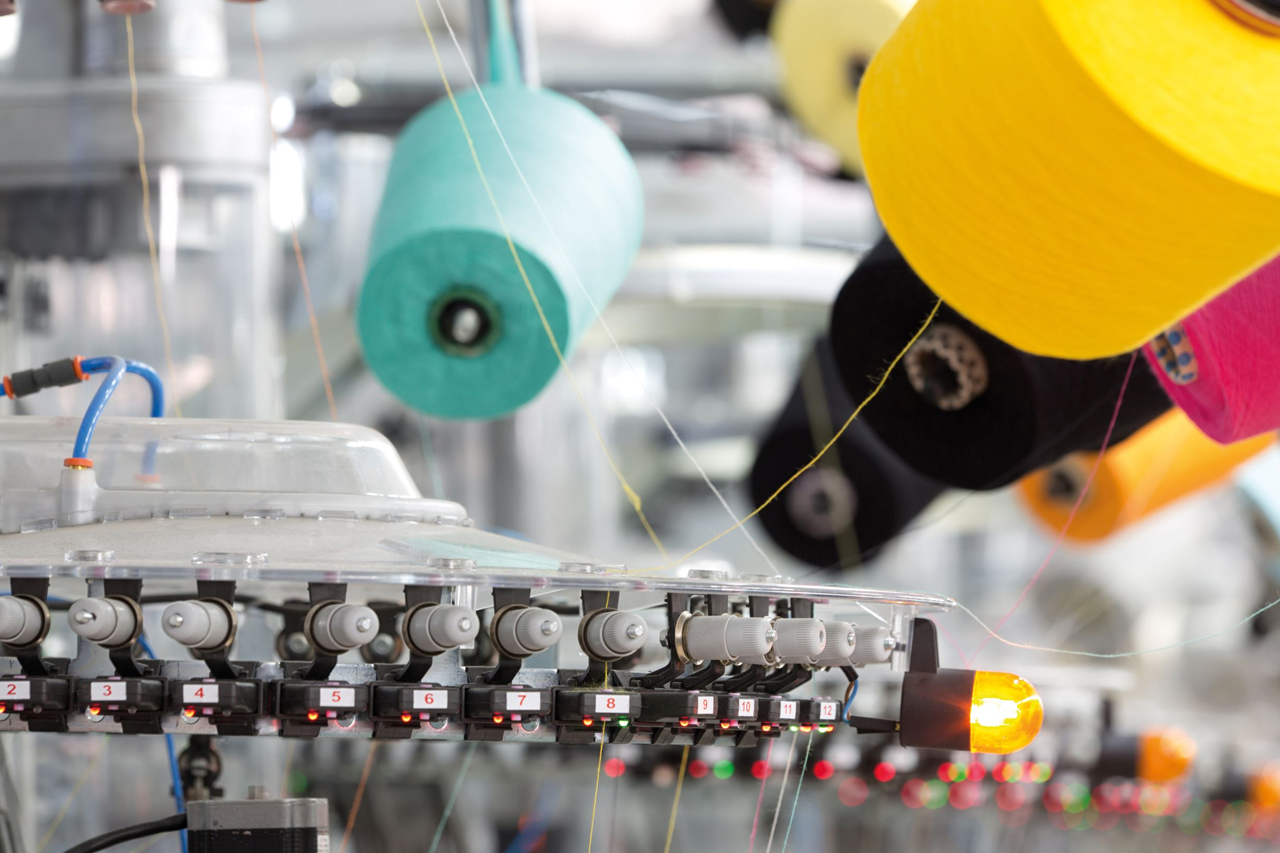

Knitting

We utilize state of the art automated knitting machines

We make sure our textile products are produced using the best machinery. And this is what gives us an edge over all other competitors in the industry.

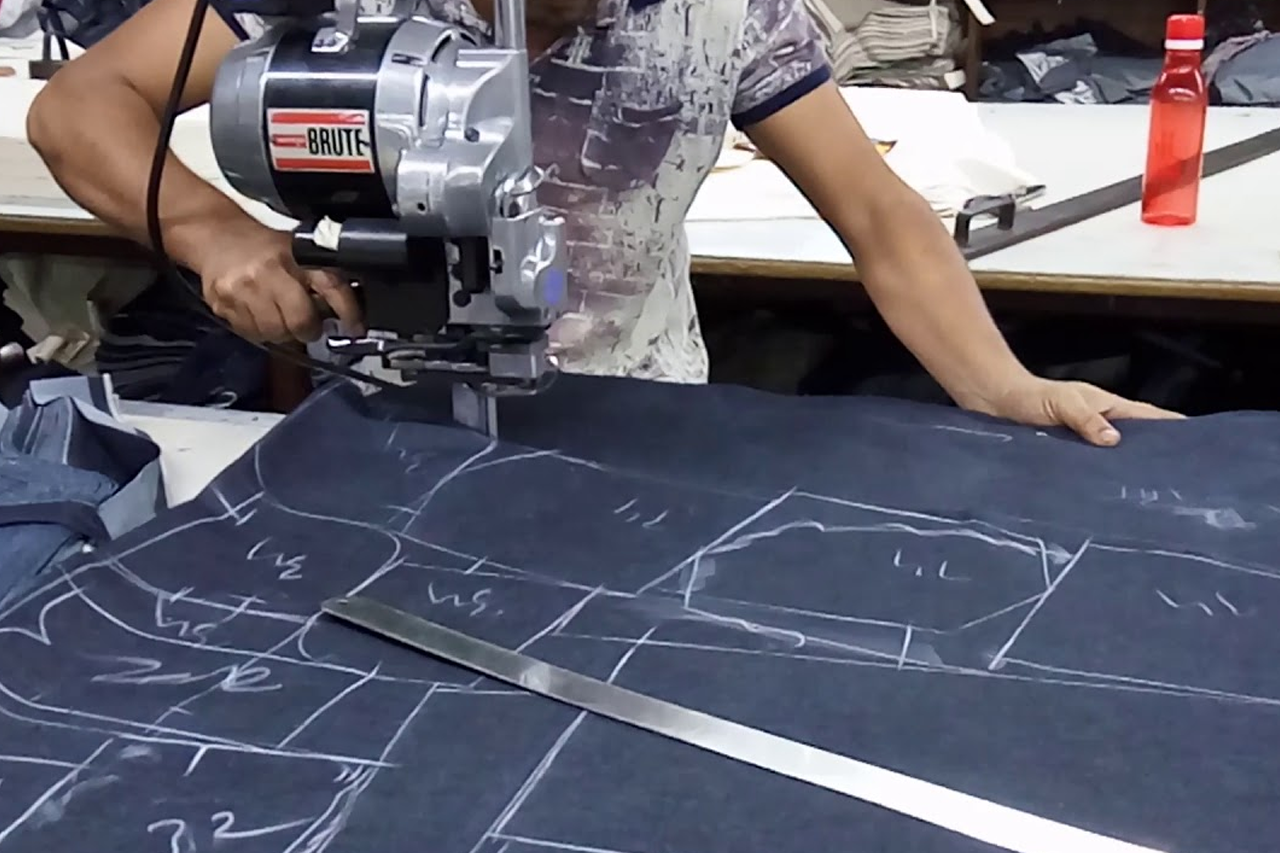

SOP's - CUTTING

Fabric Intake and Relaxation

- First, fabric is received from the fabric store along with a Fabric Inspection Report (FID).

- The cutting production team then lets the fabric relax for a specific period to prevent shrinkage.

- Fabrics with 100% Polyester/Polyamide: 24 hours

- Fabrics with some blend of Spandex / Lycra like Stretch Pongee: 48 hours

- Knitted fabrics like Scuba, with Spandex / Lycra, as they have their own mechanical stretch as well: 72 hours

Laying

- After the fabric has been relaxed, it is laid out at the cutting table

- For woven fabric, the minimum lay height is 2.5 to 3 inches.

- For knit fabric, the lay height should be 3.5 to 4 inches.

Pattern and Cutting

- Before laying the fabric, it is ensured, they have GGT marker which is reviewed to see how to get the maximum cutting efficiency to save as much fabric as possible to use for further production process rejections, like during printing/embroidery /sewing/finishing, to control the short shipment at the end

Bundling and Sorting of the cut panels or parts

- Cut pieces are then sorted and bundled according to the specific article size requirements and embellishment

Distribution to Departments

- In above process, panels that require embroidery or printing are segregated and are sent to respective departments.

- The remaining panels are given to the Receiving & Issuing (R&I) team for re-bundling and further processing but after combining together with embellished parts which are also returned to R&I team once done.

Embroidery

o help us get superior quality emblems and logos incorporated, we utilize multi-head embroidery machines

Embroidery and logo design is such an integral component of apparel and that’s why our team pulls out all the stops to produce stellar designs across the board.

Stitching

All goods undergo thorough evaluation in the stitching unit with comprehensive shipping audit

To minimize any stitching faults and to avoid finishing glitches, our team is always on standby for integral audit checks.

Finishing

Another thorough check for last minute assortment

Since every piece is custom made, we perform finishing with attention to the details. Our teams at Core Glory International conduct thorough audits to double check numbers, sizes, as well as color assortment packaging.

Quality Control

We believe in stringent quality control

There are a number of measures in place so that all goods sent out carry100% customer satisfaction.

The auditing process is an integral step before shipping

Right before shipping, our auditing team is active and on spot for careful inspection.

Packing

All boxed cartons with apparels have barcodes in place to minimize chances in shipment errors

There’s zero room for error in the professional world and that’s why we pull out all the stops for guaranteed success.